WESTFIELD – In 2013, The Westfield Museum, Inc. was awarded a Community Preservation Act (CPA) grant of $809,470 to secure the envelope of the building at 360 Elm Street, the last whip manufacturing company in Westfield.

According to Carol Martin, owner of Westfield Whip Mfg. Co. which is housed in the building, there were 40 whip manufacturers in the 1800s in Westfield. It was the primary industry in the city, giving it the name “Whip City.” Martin said the largest manufacturer shipped out as many as 25,000 whips per day during the height of the industry. She said 95% of the whips made worldwide at the time came from Westfield, which turned whipmaking from a craft to an industry.

Whips were used for horses and oxen, as an essential tool for farmers, and pioneers settling the western half of the country.

Carol Martin, owner of the Westfield Whip Mfg. Co., still makes The Westfield Whip on 1850’s industrial revolution era machines. (Photo by Amy Porter)

Martin still makes traditional “Westfield whips” on the original 1850’s industrial era machines in the company, although she admits the need and volume for them doesn’t exist anymore. Instead of whalebone, rawhide and rattan, she uses fiberglass and plastics, using the same processing and machines, and covers them in 100% cottons fiber. She said the new whips have the same action as the old rawhide whips, known as “The Westfield Whip.”

“The product is high end,” said Walter Fogg of the Westfield Historical Commission, which worked to secure the CPA grant. Martin has made an Olympics commemorative whip, which was gifted to the Olympic dressage team, and has also made whips available as commemorative pieces.

Martin’s vision now is to establish a world-class museum that will preserve the history of Westfield’s industrustial revolution past, as well as to engage in the study of its signature industry, whip-making. Toward that end, she initiated the Westfield Historic Industries Preservation Project (WHIPP), which merged with the Westfield Museum, Inc., whose mission was to create a museum featuring Westfield artifacts and memorabilia.

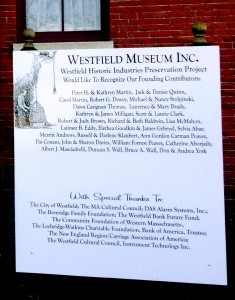

The WMI/WHIPP merger was effective as of July 1, 2012. Plans called for the restoration of the 360 Elm Street building for the museum, to include an education center and community space as well as The Westfield Room – a state-of-the-art gallery space to mount appropriate displays changing quarterly – on the first floor. The manufacturing operation will be consolidated on the second floor and serve as an interactive display where visitors will be able to experience first-hand the operation of the cutting edge 19th century technology which gave the City of Westfield its enduring nickname. A grant from the Westfield Bank Future Fund allowed WMI to engage the firm of Architecture EL for design services. Other initial grants are listed on signage in the front of the building at 360 Elm Street.

The CPA grant allowed the organization to go forward with the exterior restoration of the 1884 building, which is ¾ complete, according to Martin. They have restored and replaced the old windows. The slate roof, which was in good condition, was repaired, and six sky lights in the roof were recapped. The exterior elevator shaft was taken down, although the mechanism was kept, in hopes of restoring it one day. The bricks on the building were repointed as necessary. “The envelope is secure,” Martin said.

Carol Martin, owner of the Westfield Whip Mfg. Co. and Walter Fogg of the Westfield Historical Commission. (Photo by Amy Porter)

In order to receive the CPA grant, a preservation restriction in perpetuity was placed on the building. The restriction requires any major changes to the exterior be reviewed and approved by the Historical Commission. The Massachusetts Historical Commission took part in drafting the preservation restriction. The property was the most complicated project the Community Preservation Commission has ever done, according to Fogg.

Another condition of receiving the CPA grant was a review by the Architectural Access Board in Boston, which requires universal access to CPA projects.

Noting there was no access consideration given when the building was erected, Martin said the Westfield Museum made an agreement with the Access Board to build out the museum in four phases. As any one phase opens to the public, that phase will be fully accessible, which requires melding accessibility issues with the historic structure. Martin said they are fortunate that it can be done in phases.

“Doing anything right is a long process,” Martin said. She used as an example the American Precision Museum in Windsor, VT, which showcases early industrial revolution manufacturing and machinery. The museum, which got started in the 1960s and has an international reputation, is only open from the end of March through October.

“They are still working on their building, and perfecting display areas,” Martin said, adding “The gentleman who founded it is long gone. “

Some criticism has been directed to the Westfield Museum of late, most vocally by Westfield resident Frank Mills at recent City Council and Community Preservation Commission meetings, questioning the wisdom of putting public money into a project with zero visitation by the public, and into a building assessed at less than $200,000.

“We’re in the process and it’s a complicated process to get to the point when we can open. Carol is carrying the load by herself. If it were not for Carol and this museum and the machinery in it, the whipmaking history of the city would be gone,” Fogg said, adding, “There was a belief that when the scaffolding comes down, the doors would open,” Fogg said.

Martin also said that the CPA funds were not contingent on creating a museum, but only on securing the structure. There was no requirement that any public access be given, only permission for the Historical Commission to photograph the building.

In fact, the deed restriction states exactly that. “The Grantor shall make the lot on which the Building is sited accessible to the public (who otherwise have no legal interest or rights of use with respect to the Property) on a minimum of fifteen (15) days per year. On other times deemed reasonable by the Grantor persons affiliated with educational institutions, professional architectural associations and historical societies shall be permitted to study the Building. The Historical Commission may make photographs, drawings or other representations documenting the significant historical, cultural and architectural character and features of the Building and distribute them to magazines, newsletters or other publications, or otherwise use them to fulfill the governmental purpose of an HC.”

“The value of this collection is that it’s an intact industrial revolution business. We can show the evolution,” Martin added. The collection also includes an archival section in the attic, with 125 years of business records. She said both the exterior and the interior of the building are listed on the National Historic Register, because it is a complete record of an industry in decline.

Previously the Smithsonian has shown an interest in the machinery in the building, many of which were created in and unique to Westfield. The International Equestrian Federation also made a film which aired on the BBC in 2014, one of four segments on Martin and whipmaking in the Westfield Whip Mfg. Co.

There is also considerable interest from folks in Westfield, as well as `gear heads’ (people interested in machines),” Martin said.

“Virtually everybody who has lived in Westfield more than one generation had someone who worked in the whip industry,” she added.

Prior to the grant and the accessibility requirement, Martin did have school classes and visitors come to the Whip Manufacturing Co. to see the collection, and learn about whipmaking. “I was always willing to bring groups through. Now we can’t.” she said. Now she gives talks on the industry at the Westfield Athenaeum, the Carriage Assoc., Liberty Manor, and the Westfield Historical Society.

She said for completion of phase I of the museum, the issue is now just about accessibility. She said they are “a couple of $100,000 away” from being able to do that work.

“I so look forward to getting people through here,” Martin said.