Mark Dupuis, CEO of Heka, Inc. in grow room. (Photos by Amy Porter)

WESTFIELD – Construction is full-steam ahead at Heka, Inc. at 98 Sgt. T. M. Dion Way, as the marijuana cultivation, processing and dispensary business prepares to open in August. “There will be a big construction push next month,” Heka’s Chief Operating Officer Mark Dupuis said on Wednesday.

Dupuis said the opening was delayed from its original projection for 2017, because of the changes in the laws. “We had to slow down,” Dupuis said. “When they first started, dispensaries were only going to be selling one pound a day. Within a year, the larger ones were selling five pounds a day.”

Another law that changed in the fall allowed cannabis businesses, originally required to be non-profit for medical marijuana, to become for-profit to allow adult use. At that time, Heka Health became Heka, Inc. Dupuis said Heka went from a $4 million project, to a $10 million one.

“I started three years ago. We needed to raise more money. We’re behind for no other reason than the project ended up costing twice as much,” he said.

Heka, Inc. also received priority approval for licensing for adult use, given by the state in April to businesses already approved for medical marijuana. Dupuis said they are keeping the medical marijuana side and, as soon as the city allows adult use, will go through its permitting process. He expects that to start next month.

Dupuis has lived in Westfield for 25 years and sent his kids through school here, he said. He already owned the building on Sgt. Dion Way, home to his former business, Materials Life Cycle Management Company, which manufactured alternative fuel for coal-powered plants. After 13-14 years in business, Dupuis said the laws changed there, too, as all coal-powered plants in the state were shut down and the company moved to St. Louis.

In addition to the Westfield location, Heka, Inc. will also have locations in Pittsfield and West Springfield, which are slated to open in September. One will be just a dispensary, the other one to include cultivating, processing, and a dispensary. Dupuis declined to say more about those operations as they are changing locations.

Heka Inc. Administrative team includes Deane Gallo, V.P., Head of Security, Jack Murphy, V.P. Retail Operations, Kimberly Shattuck, Controller, Mark Dupuis, CEO.

He said he is also looking at other buildings in Westfield, noting that it will take the next 3-5 years before there’s enough supply to meet the demand. Dupuis said they will be hiring 140 employees over the next year; 14 in the cultivation facility, 15 in processing, 6 in administration and 90 in the dispensaries.

Dupuis said he has been building high volume businesses since he was 20.

For Heka, Inc.’s Westfield location, the company kept the shell of the building, and are rebuilding the entire facility out of insulated panels They also had to install a sewer line half a mile down the road to connect to the city, which cost “a quarter of a million dollars,” according to Dupuis.

Inside, the cultivation and processing departments and dispensary will all be in separated locations with key code entrances. There will also be 150 cameras, operating “24/7, 365 days of the year.” Dupuis said he has offered access to the cameras to the Police Department. “Whatever they’re comfortable with,” he said.

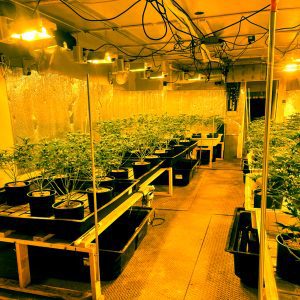

The cultivation department is almost done. Dupuis said they will be growing plants from clones, using clippings of plants rather than seeds; which reflects another change in the rules that allows clones from the market. That way they will have all female plants and no seeds, Dupuis said.

The clones will be started in boxes with nutrients and water, and they will have room for 18,500 clones. All LED lights will be used for growing, Dupuis said.

The cultivation department will have potting rooms to place plants in coco shells, and twelve grow rooms with 1,300 1000-watt lights for the 16,000 plants which will be growing at all times in the facility.

3,000 tons of air conditioning, and 15,000 quarts for humidification will keep the grow rooms at 80 degrees with 50% humidity year-round.

In the nutrient rooms where the water is managed, Heka will use a fully automated “fertigation” system, which runs hoses to each plant for automatic drip irrigation managed by sensors. They will be using city water, which will go through a reverse osmosis unit for pure water for the plants.

They will also have harvesting rooms, where employees will wear medical scrubs and use air showers after working with the plants.

The growing cycle takes eleven weeks from planting to harvest, after which they will harvest one room a week. Dupuis said they will begin cultivation in July or August, after the state inspection process is complete. Because they won’t start planting until then, the dispensaries will open with products bought wholesale from Registered Marijuana Dispensaries (RMD). Dupuis said he expects they will be selling their own product by January, 2019.

On the top floor over all of the departments are 3,000 tons of air conditioning, and 15,000 quarts for humidification. All of the grow rooms will be climate-controlled at 80 degrees with 50% humidity year-round.

The processing area in the Westfield location is 10,000 square feet, where they will be manufacturing products with raw flowers, or extracting THC (Tetrahydrocannabinol) and other cannabinoids from the oil in the plants, and using the oil to make products.

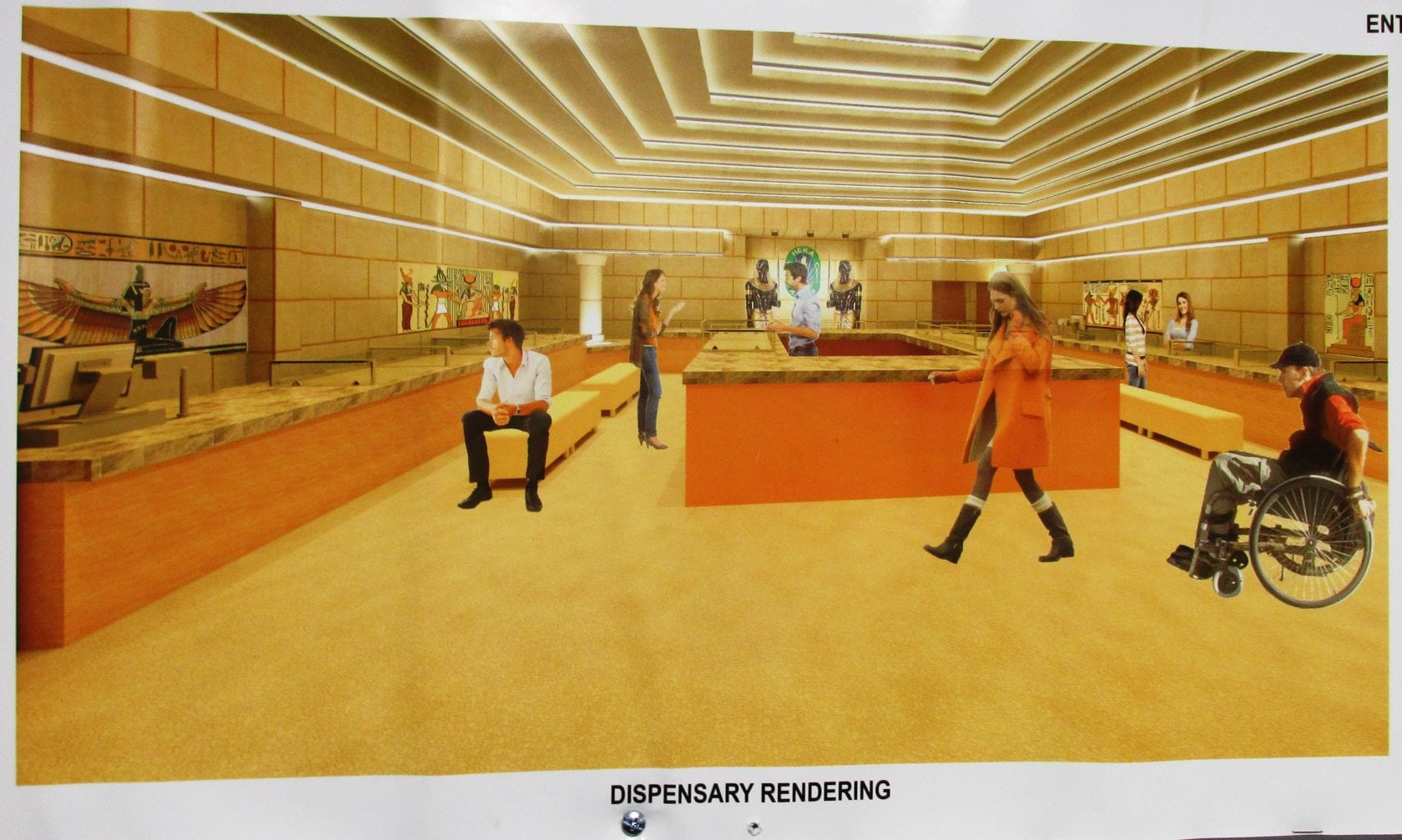

An artist rendering of Egyptian-themed Heka dispensaries that Dupuis hopes to become destinations.

They will also have a full kitchen, a testing lab, and quality and control department. “Everything will undergo monthly state inspection,” Dupuis said, giving high marks to the state process. “I applaud what they’re doing and how they’re doing this. Quality and qualified people are doing this.”

Dupuis gets excited when talking about the dispensaries, which in Westfield will be 5,000 square feet with 18 cash registers. He said the name Heka is from the Egyptian god of magic and medicine. The ancient Egyptians also issued the first known prescriptions for the use of cannabis that date back to 2,000 BC, according to Heka literature.

Dupuis pointed to an artist’s rendering of a dispensary that suggested pyramids and other Egyptian artifacts. “We’re working hard to make our dispensaries destinations, branding them with the Egyptian theme,” Dupuis said. “A gift from the gods,” he added.