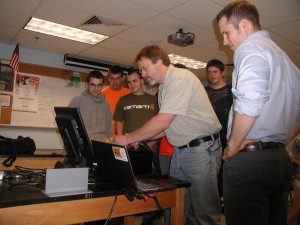

Gateway welding teacher Paul Atkinson takes a turn with the welding simulator, as his students and Seth Short look on. (Photo submitted)

HUNTINGTON – Gateway welding teacher Paul Atkinson and his students tried their hand at ‘virtual welding’ last week, an opportunity to test drive some new equipment that the school is purchasing through a grant.

Seth Short, who works for a company called Reality Works, visited Gateway on June 12 to bring a welding simulator to the welding shop and train staff and students how to use it.

Observing were Principal Jason Finnie, Assistant Principal Celeste Malvezzi, Information Technology Specialist Kurt Zinnack and Guidance Counselor Richard White. About twenty students in Gateway’s Metal Fabrication and Joining Technologies program were also in attendance and several students had the first shot at trying the simulator.

Each student will have their own account with the new system, and their “virtual welds” will be filed in their own portfolio. The machine runs two types of simulations: an exercise mode, which breaks down each welding technique taught into multiple steps; and a practice mode, which allows students to attempt multiple welds using that technique. The machine’s purpose is to have students build proper technique in a safe setting, before trying their skills with real equipment.

Once a virtual weld is finished, the simulator provides diagnostics on arc speed, angle, heat, bead height, dexterity and voltage on the practice weld. These diagnostics will read differently if the virtual weld is assigning the weld to different types of metal, Short said.

Seth Short (left) gives a technique pointer to Gateway student Dalton Spaeth, as he takes a shot at using the welding simulator. (Photo submitted)

“It’s going to save a lot of material, gas and wire,” noted Atkinson. Short confirmed that schools using this system have saved up to 75 percent of the cost of consumable materials.

Gateway Regional High School is receiving $23,855 in grant funding to purchase a welding simulator for its vocational Metal Fabrication and Joining Technology program. It is one of 25 vocational programs in the state to receive a Vocational School Equipment grant.

Gateway Regional High School accepts incoming school choice students.